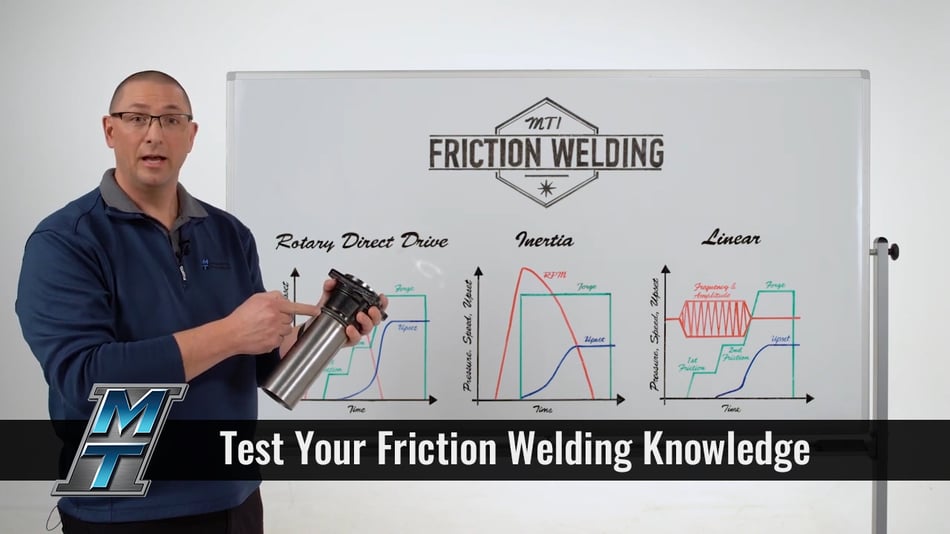

If you’ve been following along with our Whiteboard Wednesday series, you may be starting to feel confident in your ability to differentiate between our joining technologies.

In this episode, we’re going to put your knowledge to the test with a little Friction Welding Quiz Show!

First, we’ll show you a welded part. Then, you’re going to decide whether that component was welded with Direct Drive, Inertia, Linear or Low Force Friction Welding.

Let’s begin.

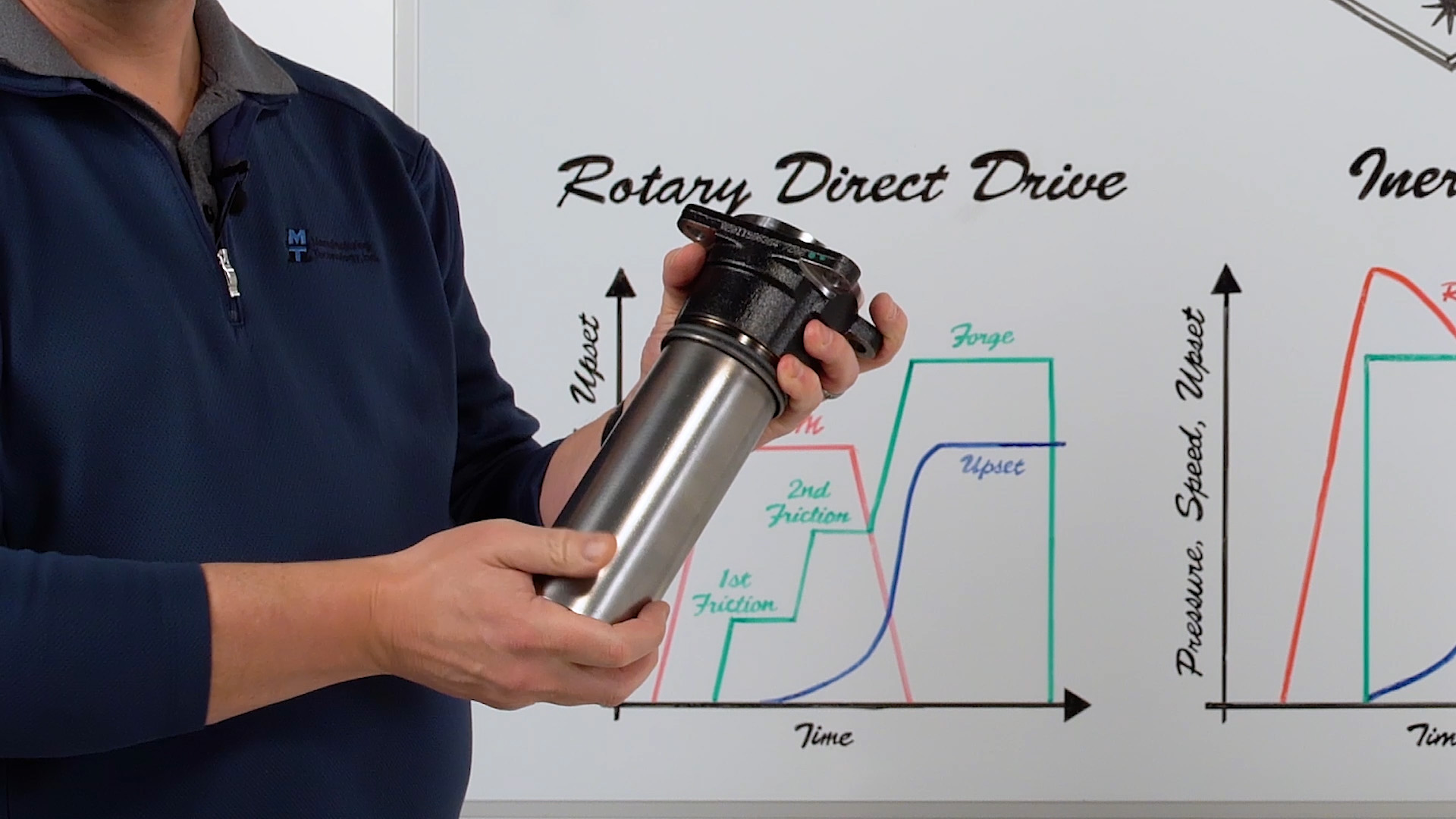

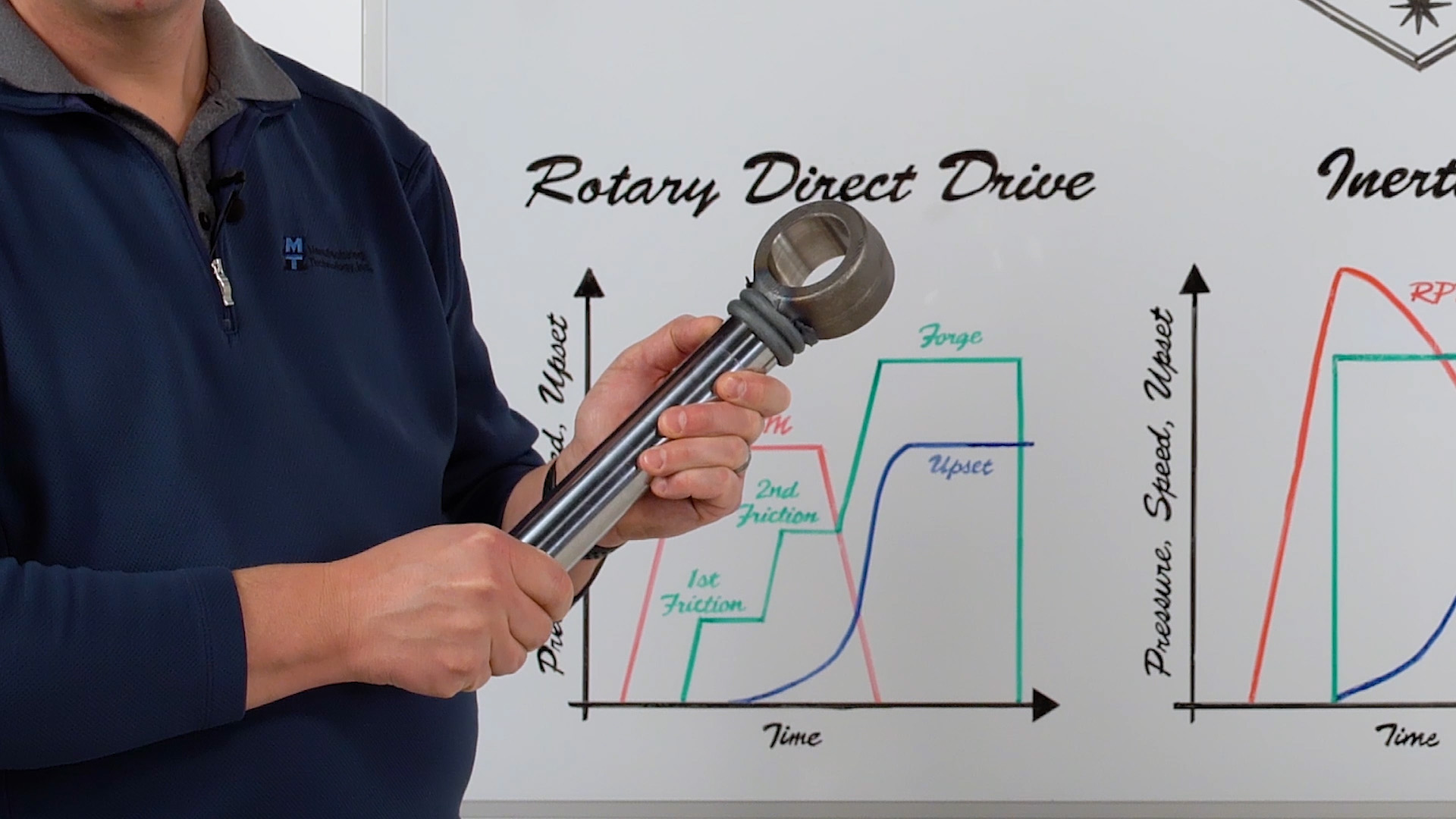

QUESTION: This is an axle. It’s a traditional, high-volume automotive application for Rotary Friction Welding. So… which Rotary technology do you think is best-suited for this axle?

ANSWER: Traditionally, this is a Direct Drive Friction Welding application. We can put as much heat into it as we want, and then after welding, we would likely remove the flash with a two-axis flash removal tool.

The challenge is… we can’t remove the ID (Inner Diameter) flash, which hurts us from a fatigue performance perspective.

While this is traditionally a Direct Drive application, we can look at this another way. We could also use Inertia Friction Welding on this application to improve the cycle time and use shearing instead of turning to remove the flash.

We can even take this one step further and imagine this part being joined with Low Force Friction Welding. If we utilized our newest joining technology, we would get a flash bulge instead of a flash curl, making the flash much easier to remove on the OD (Outer Diameter) and we don’t have to remove it on the ID while still maintaining our fatigue performance.

Let’s check out another application.

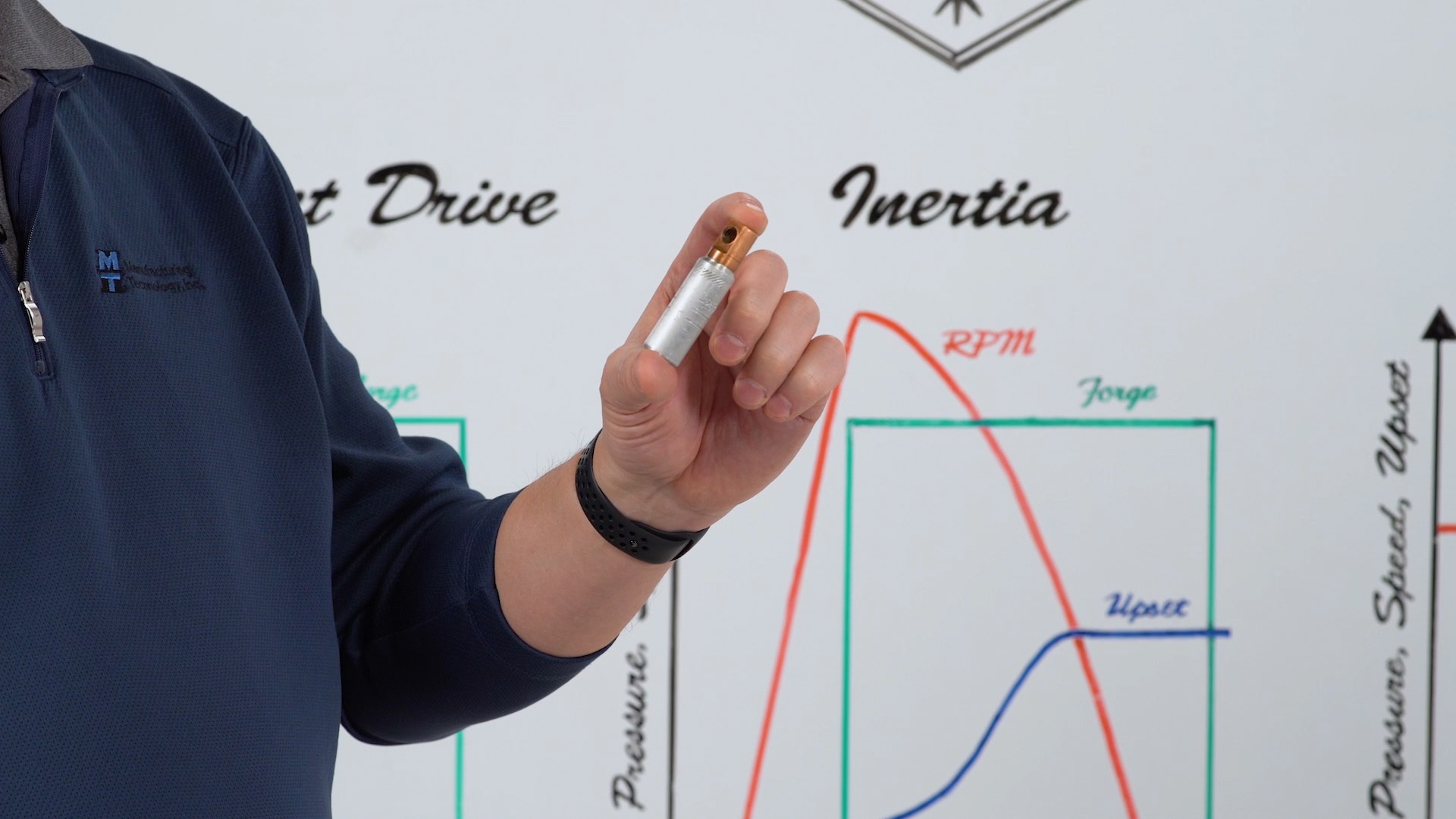

QUESTION: This is a high-volume electrical connector made out of copper and aluminum. Which technology should we use?

ANSWER: Because it’s a round part, you may have defaulted to Direct Drive or Inertia Friction Welding. Because these parts are welded all around the world, most people select Direct Drive Friction Welding. But because it’s such a high-volume part, you may be able to shave a few seconds of cycle time by choosing Inertia Friction Welding – that’s what we do at MTI.

But because this part is also a bimetallic, we challenge you to consider using Low Force Friction Welding, which would allow us to bias the heat towards the copper and try to get some copper upset, as opposed to just upsetting all of the material out of the aluminum. By doing this, we could achieve a slightly stronger weld with Low Force Friction Welding.

Let’s check out another bimetallic part.

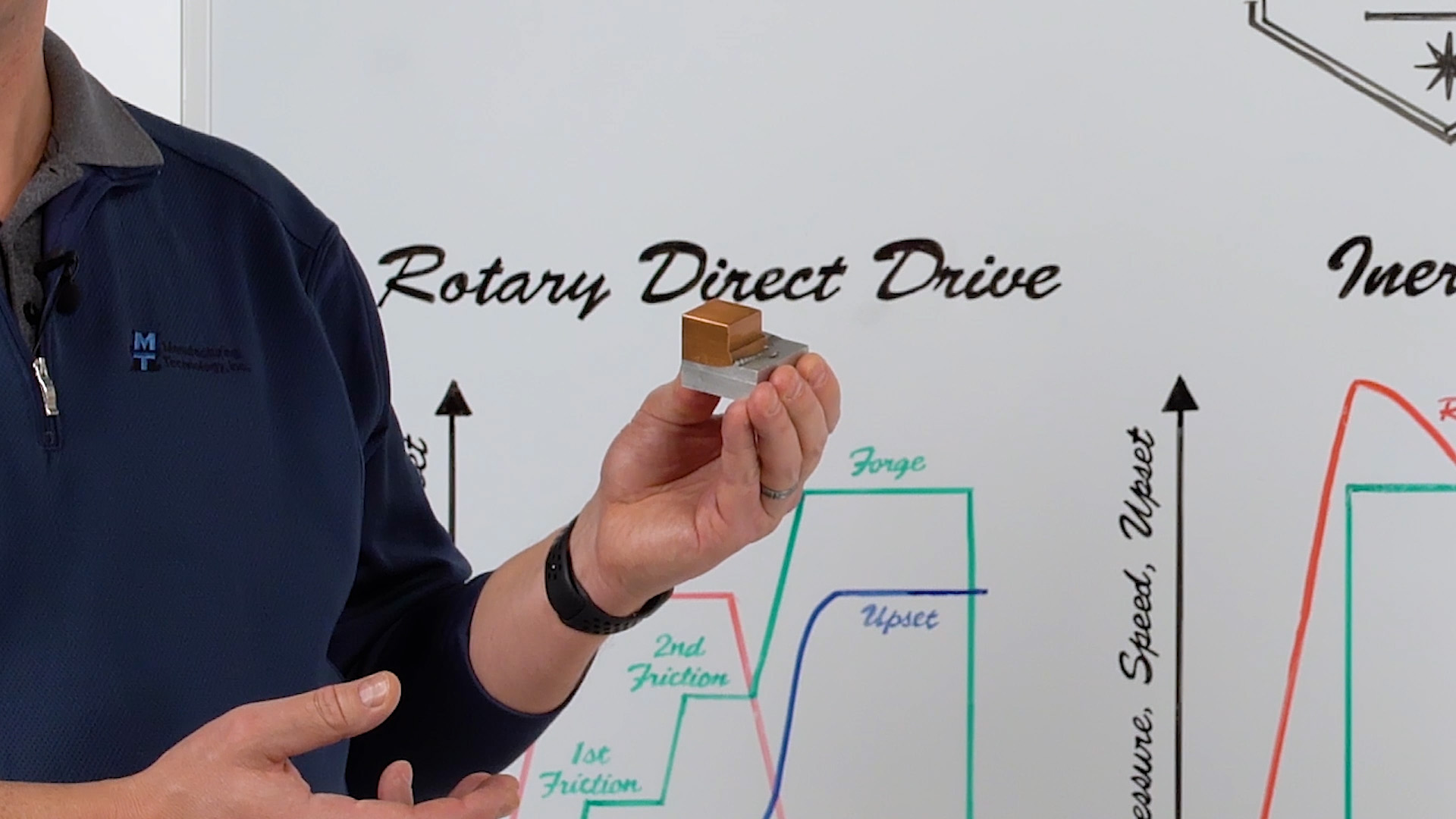

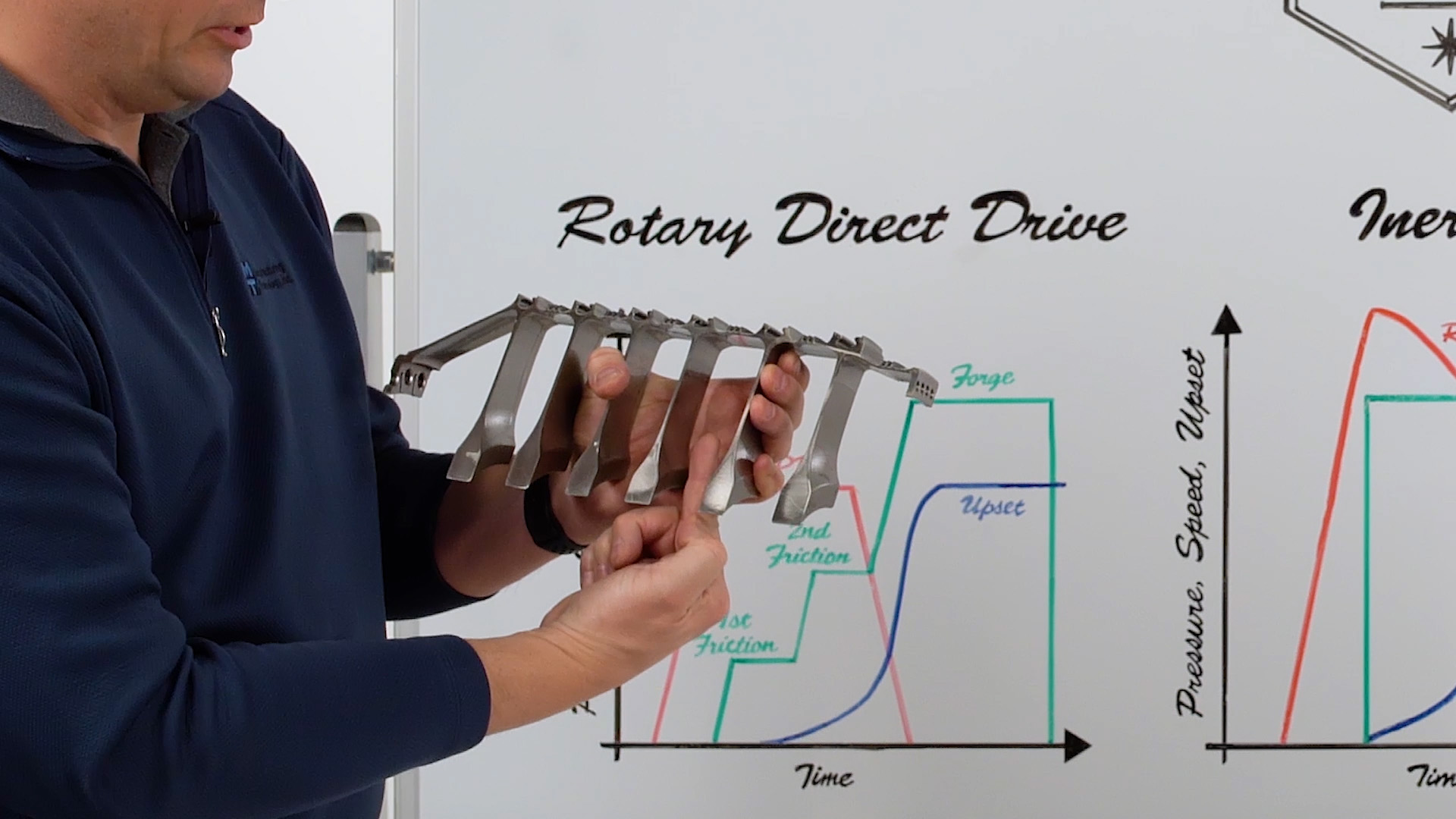

QUESTION: This component is also copper to aluminum… but because the part is not round, we won’t be able to rotate the pieces. So… which technology should we use?

ANSWER: If you were thinking Linear Friction Welding… you’re correct – at least partly! While this part can be achieved with Linear Friction Welding, it can be vastly improved with Low Force Friction Welding. Because this part is also a bimetallic, we can again bias the heat toward the alloy that’s more difficult to weld.

Let’s take a look at a larger part.

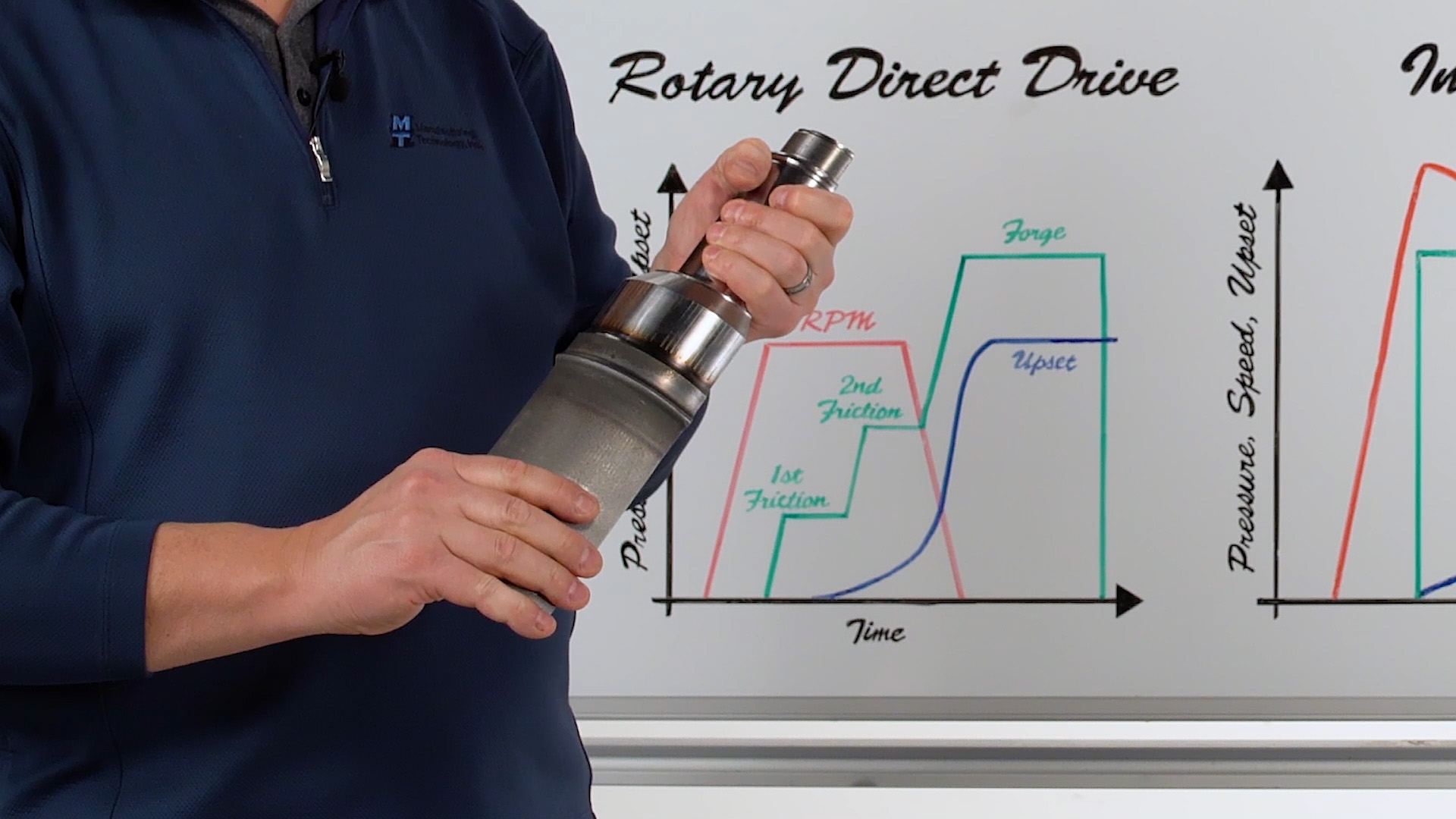

QUESTION: This is a classic hydraulic cylinder rod - another round component. Which technology should we use?

ANSWER: The classic approach for this application is Direct Drive Friction Welding, but if you’re welding a mild steel component, you could also use Inertia Friction Welding and achieve this weld with a lower cycle time.

When using a hardenable steel, we want to be able to extend our weld time and get a lot of heat in so the cooling rate is controlled and we aren’t forming martensite, achieving great fatigue performance.

But the longer weld time does create a challenge – more upset. Now we are faced with a big flash curl that we need to remove using a two-axis flash removal tool.

So… what if we used Low Force Friction Welding for this application, too? We could trade our flash curl for a flash bulge and we could gain the ability to control the cooling rate with pre-heat or post-heat so we’re not getting long weld times. This would allow us to weld more parts per minute.

This next part is a bit tricky. Think you can identify the technology on your first guess?

QUESTION: This is a specialized component. It’s a 350 millimeter-diameter barrel, where we need to make welds between each section. It’s a large diameter, thin-wall tube. So… which technology would be best?

ANSWER: If we’re thinking about this from a titanium perspective, you may be thinking Direct Drive Friction Welding. The reality is… when we combine titanium and Inconel on one machine… the titanium can be done with Direct Drive… but the Inconel cannot, due to drive motor torque limitations. Therefore, this is a classic Inertia Friction Welding application.

Any time that we have a part with a large diameter and thin wall tubes, we should start considering Inertia Friction Welding… especially with Aerospace materials.

But we challenge you to think about this part as a Low Force Friction Welding application. Because this part would require us to machine the flash off after welding, getting a turning tool between each part would be extremely difficult. However, if we create a low upset weld and have a little bit of bulge, we wouldn’t necessarily have to remove it. So now, Low Force becomes a very competitive technology and shrinks the machine footprint.

Let's try another automotive component.

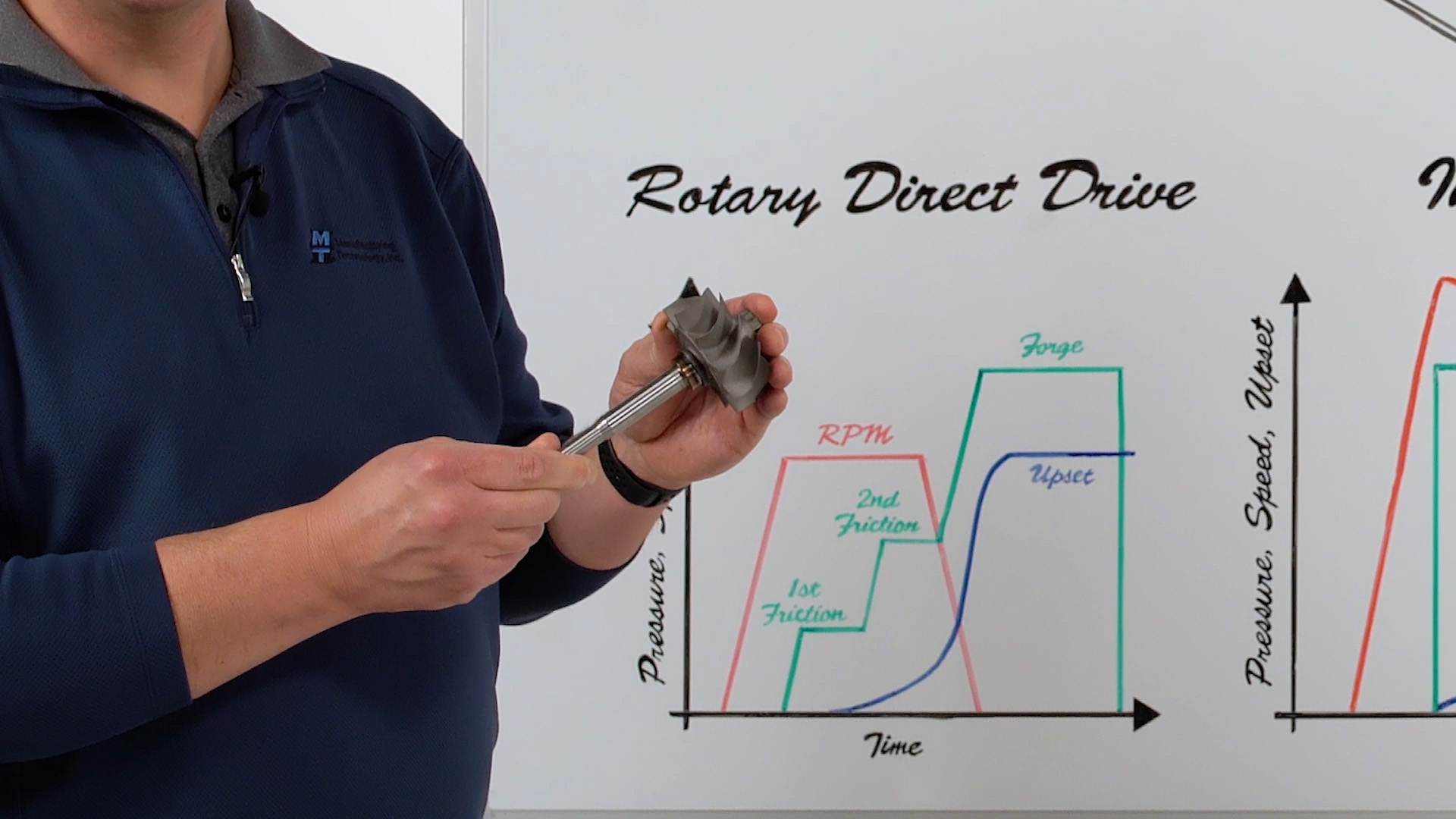

QUESTION: This is a high-volume automotive turbocharger wheel. It’s made up of an Inconel casting and a steel shaft. It’s a round component… so which technology would be best to join this component?

ANSWER: While Direct Drive Friction Welding can make these welds very effectively, it does pose a challenge. If we miscalculate the timing of our speed coming down and our forge force going up, we can experience a quality issue.

MTI uses Inertia Welding because it’s very easy and straightforward – it’s our standard process.

But because this part is also a bimetallic, you should consider Low Force Friction Welding as a great option because, again, we can bias the heat towards the Inconel and get a really fast weld. Therefore, Low Force Friction Welding would be a great alternative to pursue for turbocharger wheels.

Let’s check out another high-volume automotive application.

QUESTION: This is an e-axle. But with this axle, we’re welding a spindle to the tube. This is a 150-millimeter diameter component and it’s done with hardenable steels. So… which technology should we use?

ANSWER: The predominant technology for this would be Direct Drive Friction Welding, accomplished with a double-ended machine. Because it’s a hardenable steel, we have to put a bunch of heat into the component to ensure we are controlling the cooling rate to avoid martensite.

But again, we can’t get in to remove the ID flash, so the design of the component needs to take into account that there’s a mechanical notch with respect to fatigue performance.

Here’s a twist – the part pictured above was actually welded with Low Force Friction Welding! You can see the flash formation is significantly smaller than what would be produced with Direct Drive. Plus, on the ID side, we don’t need to remove the flash because it’s so low. The fatigue performance of the Low Force part was equal to or exceeding the part produced using Direct Drive. Plus, our cycle time was lower and we welded it on a 10-ton machine instead of a 125-ton machine.

By using Low Force Friction Welding to join this part, we gained five key benefits:

- Ability to hold concentricity

- Part deflections

- All desired tolerances from component

- Same fatigue performance due to ID flash morphology

- No need to remove OD flash

THE CLEAR WINNER

If you’ve been keeping score… you’ve likely noticed there’s a trend here – Low Force is the clear winner for each of these applications. That’s because we’ve been able to take aspects of our legacy technologies and combine them into one powerful, innovating joining technology.

WHICH TECHNOLOGY IS RIGHT FOR YOU?

Whether your next component is Direct Drive, Inertia, Linear or Low Force, MTI has the know-how to join your components OR build a machine to put on your own shop floor.

Take the first step by connecting with one of our knowledgeable sales engineers today!

LinkedIn: https://www.linkedin.com/company/manufacturing-technology-inc

YouTube: https://www.youtube.com/c/ManufacturingTechnologyIncMTIJoiningSolutions/videos

MTI UK

MTI UK  FWT

FWT