In our last episode of Whiteboard Wednesday, we introduced you to a brand-new style of solid-state joining, Low Force Friction Welding.

Need a refresher? Remember, in Low Force Friction Welding, we add preheat energy to the part, allowing us to make the same high-quality, solid-state joint at a fraction of the force.

So, what might motivate a customer to choose Low Force Friction Welding over traditional friction welding?

This new solid-state joining process touts four key values:

- Less flash formation

- Smaller machine size

- Reduced cycle time

- Preheat and post-heat capabilities

LESS FLASH FORMATION

One of the most noticeable differences between traditional friction welding and Low Force Friction Welding is the appearance of the flash.

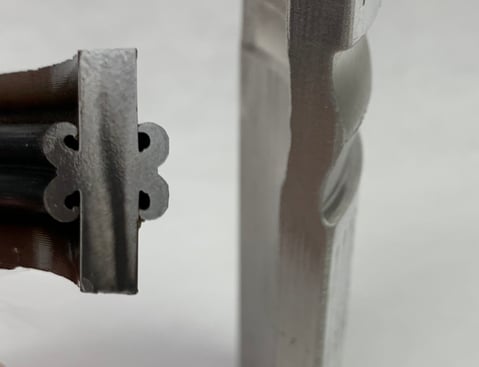

Traditional Rotary Friction Weld vs. Low Force Friction Weld

Traditional Rotary Friction Weld vs. Low Force Friction Weld

Above, you can see a side-by-side comparison of a traditional Rotary friction weld and a weld produced by Low Force Friction Welding. You'll notice the flash is larger and more prominent on the traditional friction weld than what you see on the Low Force weld. You'll notice the flash on the traditional friction weld resembles a ram's horn while the Low Force weld takes on more of a bulge-like appearance.

Low Force Friction Welding allows us to control the amount of upset to match a customer's request. With different combinations of preheat and relative motion, we can alter the appearance of the flash to benefit a customer's processing downstream of the friction welder.

SMALLER MACHINE SIZE

Because we're using low force, this allows us to decrease the size of the machine. If we're using less forge force to make the same weld, the amount of steel we need in the machine frame and the complexity of the tooling both decrease. As a result, we have a smaller machine that takes up less space on a customer's production floor.

We can also decrease the size and footprint of the machine — all because of different process forces.

REDUCED CYCLE TIME

Since we're using an external heat source in Low Force Friction Welding, we can add more preheat energy and get that energy into the part faster than we could with traditional friction welding.

Therefore, the overall cycle time, or the time it takes to produce a weld, decreases. This can be a really strong driver for high-volume producers, like many of our automotive customers.

PREHEAT AND POST-HEAT CAPABILITIES

We know that Low Force Friction Welding involves an element of preheat.

But because we have that heating capability built into the machine, we can use that same energy source to perform post-weld heat treatment on the parts. That might save the customer another piece of equipment in their production line.

All four of these benefits can increase the value of using Low Force Friction Welding compared to traditional friction welding.

MTI is the only company in the world to have developed, designed and manufactured Low Force Friction Welding machines operating in production today.

Explore these resources to find out how Low Force Friction Welding offers solutions to the rail and other industries.

MTI UK

MTI UK  FWT

FWT