MTI customers are helping us drive positive change in manufacturing every day. Our latest innovation — a double-ended Rotary axle machine — is a perfect example.

Based on input from our customers, we’ve engineered a solution that uses advanced technology to increase efficiency, control and cost effectiveness in axle production.

What We Heard

Our customers in the automotive industry asked MTI for enhanced production capabilities such as:

- Post-weld, finished axles that require no further machining

- Ability for a single machine to process drive or trailer axles

- Automated axle-length adjustability, to eliminate manual software changes

In response to these requests, MTI engineered a double-ended Rotary axle machine that accommodates all of these needs, and more. In fact, it meets drive and trailer axle industry standards, so you can match your industry’s demand on capability and capacity.

How We Did It

The challenge: to build a unique solution that would offer maximum flexibility, and maximum accuracy. The result: a fully automated machine that leverages rotary friction welding technology to provide work cell automation.

The MTI double-ended Rotary axle machine provided:

- Improved production capability with new quick change part contact tooling that reduces change out downtime on the machine

- Easy scheduling of multiple axle production runs on a single machine

- Ability to deliver fully finished axles for various applications, all with precision part accuracy

Additional details — like independent mandrel clamp controls that help minimize distortion, and enhanced spindle positional control —improved flash debris removal also help make the production process easier, and the parts even better. Plus, the machine itself is work cell-ready, so we can drop in robots, or engineer a linear overhead gantry to fully automate the process including spindle destacking and axle orientation on the input to the machine.

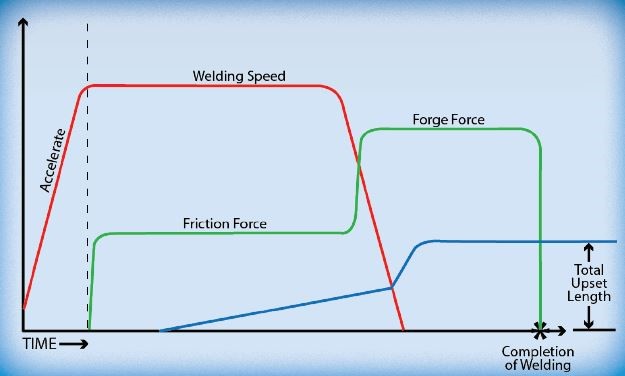

Direct Drive Friction Welding

The MTI double-ended Rotary friction machine was designed with our customers’ needs in mind. We applied our knowledge of friction welding technologies to the right application. In this case, it was Direct Drive Friction Welding, which is the standard for axle production. Here’s how that process works:

1) A single part is rotated while the other stays stationary.

2) A low friction force generates heat at the weld interface.

3) A second friction forge force is applied to generate more heat to further soften materials.

4) Energy input is decreased; full forge load is applied, causing soft material at the weld line to extrude.

5) Forge force is maintained to allow the part to cool.

Ask us about it!

MTI’s newest, most innovative double-ended, Direct Drive, Rotary friction welding machine can increase your throughput with little or no scrap, increase your revenue, and decrease your operational costs. Find out more about it today, when you contact MTI.

MTI UK

MTI UK  FWT

FWT