A state of the art Rotary Friction Welding (RFW) machine developed and built by South Bend based Manufacturing Technology Inc., is leaving Michiana to begin a 4,000 mile journey to the United Kingdom. The final destination is the Manufacturing Technology Centre (MTC), a research facility for new manufacturing techniques that bridges the technology readiness gap between development in academia and execution in industry. The machine is designed for research and development on jet engine components for companies like Rolls Royce, General Electric, and Pratt and Whitney.

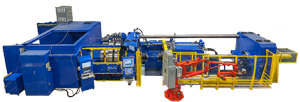

The MTC-300, which incorporates the latest advanced features in Rotary Friction Welding, extends the capability of the welding process and allows for greater control, tighter tolerances, and greater efficiency necessary for aerospace manufacturing. “The intent of this machine design is to improve friction welding capability in order to produce very near-net shape forgings, and MTI has delivered on that capability,” commented Dan Adams, Vice President of MTI.

“This took a company-wide effort to design, develop, and deliver,” continued Adams. “We’re excited about the delivery to MTC in the United Kingdom, and equally excited about bringing the advancements from this project into other areas of our product line.”

Shipment and delivery of the MTC-300 ton machine is the culmination of three and a half years of engineering and development at MTI. The MTC-300 is the show piece of the MTC facility and is scheduled to begin development work in July 2014.

Rotary Friction Welding is a joining process which involves holding one part stationary while rotating the other. The two parts are then forced together under pressure which creates friction and heat, reaching the material’s forging temperature without melting. The RFW process is complete when the weld interface cools; resulting in the previous two parts being bonded at the molecular level.

MTI has established itself as a leader in the aerospace industry for all disciplines related to friction welding. In addition to Rotary Friction Welding, MTI also serves aerospace with its Linear Friction Welding and Friction Stir Welding technologies. MTI has delivered machines to NASA, Boeing, GE, RollsRoyce, Pratt and Whitney, and many of their tier one suppliers. A family owned business founded in 1926, MTI employs 174 people in their South Bend, United Kingdom, and China locations.

To learn more about MTI, visit our website or watch our Whiteboard Wednesday video series on friction welding.

MTI UK

MTI UK  FWT

FWT