Good things do come in small packages! Check out our newest Low Force Friction Welding machine we call the Microwelder.

Traditionally, friction welding has been a solution for parts large enough to withstand the force applied to create a solid-state weld. In the past, the smallest machine MTI ever built was a Model 40 that was capable of welding solid steel bars just under 5mm - about the diameter of a drinking straw. That machine could generate 500 pounds of force!

But now there is a machine that joins parts much smaller, MTI’s Microwelder. This machine has all the valuable benefits of Low Force technology but is specially designed for the smallest of parts. Low Force Friction Welding and the Microwelder allow us to balance the heat between these two components so we can make a weld with significantly less force - six pounds of forge force to be exact! Moreover, Low Force Friction Welding offers greater flexibility to support the emerging challenges of new materials, part geometries and sizes as industries look toward the future.

The Microwelder opens the door to an exciting new range of applications including consumer electronics and dental/healthcare equipment which can now benefit from solid-state joining and higher integrity welds. Applications once too small to be joined with existing traditional and Low Force Friction Welding machines are now possible with the Microwelder.

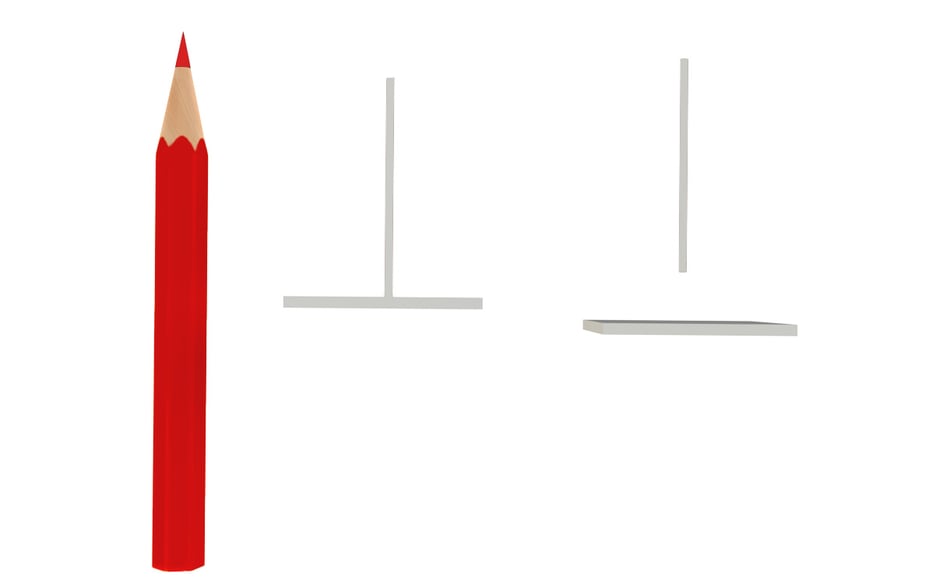

This particular aluminum bar to aluminum plate application has a weld interface of one square millimeter– which is the diameter of pencil lead! The Microwelder was designed and engineered with the smallest parts in mind and resides with our collaborator, EWI in Columbus, Ohio. The Microwelder is ready for your weld development work - contact us today to see if it’s the right fit for your project.

What is Low Force Friction Welding?

Low Force Friction Welding is the use of an external energy source to raise the interface temperature of the parts being welded, reducing the process forces required to make a solid-state weld compared to traditional friction welding. MTI is the only company in the world to have developed, designed, and manufactured Low Force friction production machines that are operating in industry today.

Because less force is used, the Low Force Friction Welding process has many advantages over traditional friction welding, opening the door for smaller applications and new possibilities. As industries encounter new joining challenges, such as vehicle electrification and the requirement to rapidly weld small conductive bimetallics in battery power systems, Low Force Friction Welding machines can provide a solution to previously unweldable metal combinations and sizes. Our Low Force technology also offers these benefits:

- Joining of Components Previously Limited by Friction Welding

- Smooth Flash

- Low Upset

- Reduced Weld Cycle Time

- Low Process Forces

- Part Repeatability

LET'S GET STARTED

Are you curious if your part can be welded on the Microwelder or do you have a unique application you need a solution for? MTI can design and build custom tooling for this machine to ensure your unique part fits perfectly. Contact us today to get started.

MTI UK

MTI UK  FWT

FWT