From Low Force Friction Welding to Friction Stir Welding, MTI specializes in several different types of friction welding processes. But in this article, we will explore our Inertia Rotary Friction Welding technology and explain how it works and outline how it could be beneficial in your next project.

Friction Welding Principles:

Like most friction welding methods, to create the bond, the general principles of the process are:

- Imparting relative motion under load to create friction

- Using the friction to generate heat between the materials to forging temperature

- Application of load to forge two parts together.

Friction welding is considered to be a solid-state joining process that that does not require any shielding gasses, fluxes or third party materials to bond.

How Inertia Friction Welding Works

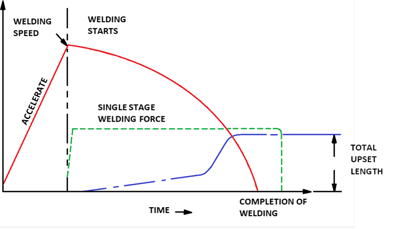

Inertia friction welding uses kinetic energy with applied force to join parts together. Like all rotary friction welding, the process is started by rotating one part in a chuck while the other remains stationary in a clamp. With inertia friction welding, the chuck has an assembly of flywheels to store kinetic energy. By accelerating the chuck and flywheels up to a desired speed, this will provide the required kinetic energy to bond the materials. Once the flywheels are up to speed, the motor driving the chuck and flywheels is disengaged and the flywheels coast, storing all the kinetic energy.

At this point the stationary part is engaged into the rotating part under forge load pressure. This is the forge force which controls the energy input of the weld and is maintained throughout the entire process. This creates friction between the parts and results in heat at the weld interface. When enough heat is created, the materials will begin to soften and will then begin to extrude and shorten.

Upsetting happens when the parts start to bond, and the softened materials are extruded out at the weld interface between the two contacting surfaces. Again, the extruded material, which is referred to as flash, self-cleanses any surface contaminants. The softened materials will continue to push out at the weld interface until all the kinetic energy is complete, the rotation of the part stops, and the upsetting ends. When the rotation stops, the weld is complete. The forge force is still maintained for a short period of time allowing the consolidation of the welded joint.

Once this process is completed, the two original parts are now 100 percent bonded together creating a fully joined, solid-state part. The time it takes to complete a weld from start to finish varies depending on the power input placed upon the two parts.

Inertia Friction Welding Advantages:

The benefit of the Inertia weld to direct drive welds is that it creates a smaller heat effected zone thus creating a smaller flash and faster weld time.

- Narrower heat affected zones

- Shorter weld times

- Bi-metallic bonding of two different materials (e.g. copper to aluminium)

- Ease of monitoring – RPM and pressure

- No clutches, no brakes

- Pre-calculable parameters allow process to be mathematically scaled

- Angular orientation after welding of ± 1º

Rotary Friction Welding is one of the most economically efficient material bonding techniques - providing expanded design and manufacturing adaptability, unrivaled quality and critical cost reductions. In many instances, the choice to embrace the rotary friction welding process can bring about significant benefits.

For more information on friction welding or how the process can help with your manufacturing processes, please feel free to contact me.

MTI UK

MTI UK  FWT

FWT