MTI's new range of FWT Direct Drive friction welding machines has all the advantages of two companies coming together under one umbrella. Bringing together design, manufacturing skills and friction welding experience, the FWT line of machines offers the best of both companies while providing a high quality and cost-effective solution for our customers.

Sleek Design and Solid Quality

A standard machine design with a straightforward and streamlined exterior, the FWT friction welders are user-friendly and configurable. The line of friction welding machines ranges from 5 tons for the smallest of part diameters, going up through the tonnage range of 125 tons welding large Drill Pipes, Piston Rods, and Axles.

The Direct Drive friction welders are collaboratively designed by FWT and MTI’s experienced engineering teams and manufactured at our new facility in Pune, India. All machines are built to MTI's strict quality control standards with components that are sourced from globally recognized suppliers. All machines are fully CE certified for the European market.

Adaptable to Your Needs

Different manufacturing problems require different solutions, and with the FWT line of Direct Drive friction welders we provide our customers with a select number of popular configurable options:

- Automation - Fully or semi-automated systems are available, reducing operator error and elevating production. Machines can seamlessly integrate into an existing production line or a fully automated isolated production cell, offering efficiency, further production cost-savings and increased productivity.

- Tooling - Respond to changing customer demands. Fixture clamping and chuck options allow you to dramatically reduce changeover time and increase part number variants within the friction welder's working limits.

- Flash Removal - Eliminate steps of pre or post-weld production. Our Direct Drive machines include several options for a flash removal system capable of single or double axis flash removal and multi-tool flash removal to perform several operations such as profile flash machining and pre-weld face preparation machining.

A Robust Process Inside a Standard Machine

FWT machines utilize sophisticated Direct Drive friction welding technology. A proven and reliable solid-state joining process, Direct Drive has been used in many industries for decades, especially the automotive industry. The process offers several advantages over traditional joining methods—including stronger welds, faster cycle times, and the ability to join bimetallics.

- Higher quality welds - Friction welding produces joints of forged quality. This results in superior weld properties compared to more traditional processes, like MIG or TIG welding and ideal for safety critical components.

- Reduced Weld Cycle - The friction welding process is significantly faster than more conventional methods of welding. Joining times are very fast and the majority of friction welds can be accomplished in just a few seconds.

- Bimetallics - Friction welding is the most effective technology available for joining dissimilar metals, also known as bimetallics. Because of differences in melting points, many bimetallic combinations are impossible to join using fusion processes. Materials like copper to aluminum and stainless steels to low carbon steels are all possible with the friction welding process.

As part of the MTI Group, FWT and MTI supply machines globally together, bringing our extensive knowledge and experience of friction welding to the global reach of MTI.

MTI’s Global Service and Spares

What truly sets FWT Direct Drive friction welders apart from other standard supply Direct Drive machines is that they are fully supported by MTI's global service team in both the US and UK. MTI remains dedicated to providing reliable, comprehensive service in North America, Europe, and all over the world, including:

- Machine installation at customer facility

- Field Service including annual services, emergency support, breakdowns, and maintenance

- Spare parts

- Warranty periods

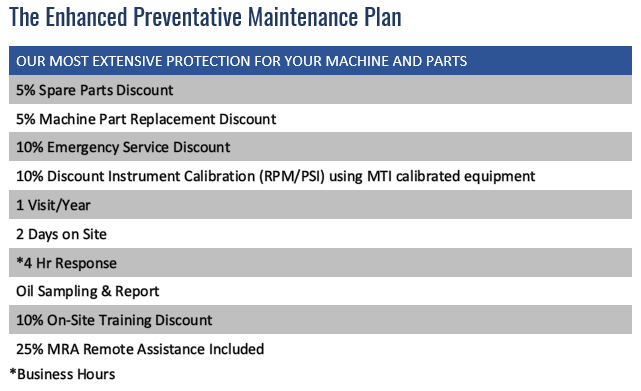

To further enhance the support of your machine, MTI offers extended warranty and preventative maintenance packages for all of our machines including FWT. MTI is dedicated to providing world-class support to our customers no matter where they are located.

MTI Can Solve Your Problems

If you're interested in learning more about our FWT line of machines, contact our technical sales team! We’ll build a machine that makes your part, we’ll make the part for you, or we’ll help you make the part even better.

MTI acquired Friction Welding Technologies Pvt. Ltd. (FWT) in 2022.

LinkedIn: https://www.linkedin.com/company/manufacturing-technology-inc

YouTube: https://www.youtube.com/c/ManufacturingTechnologyIncMTIJoiningSolutions/videos

MTI UK

MTI UK  FWT

FWT